Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The primary aim is to attain consistent, high-quality outcomes by figuring out the root causes of errors and addressing them. Six Sigma uses data-driven strategies, usually involving statistical analysis, to measure and reduce the variability in processes. By focusing only on what supplies worth to customers, companies can improve the general high quality of their products. It allows them to fulfill their customer’s needs extra effectively and offer new, innovative solutions to assist them stand out from the competitors.

Lean focuses on waste elimination, process, and delivering worth, whereas Agile focuses on prospects, mitigating uncertainty, and delivering working software. The two pillars of Lean are steady improvement and respect for folks. When used appropriately, these guiding principles inform smarter decision making and guide organizations towards turning into more healthy, more productive methods. It’s important to keep in thoughts that Lean methodology isn’t restricted to eradicating waste and increasing efficiency. A nearer examination of the seven Lean principles reveals a give attention to continuous enchancment, creating organizational knowledge, and respecting Lean staff members across all levels of the corporate. Simple Agile is dedicated to helping groups enhance their processes and agile methods.

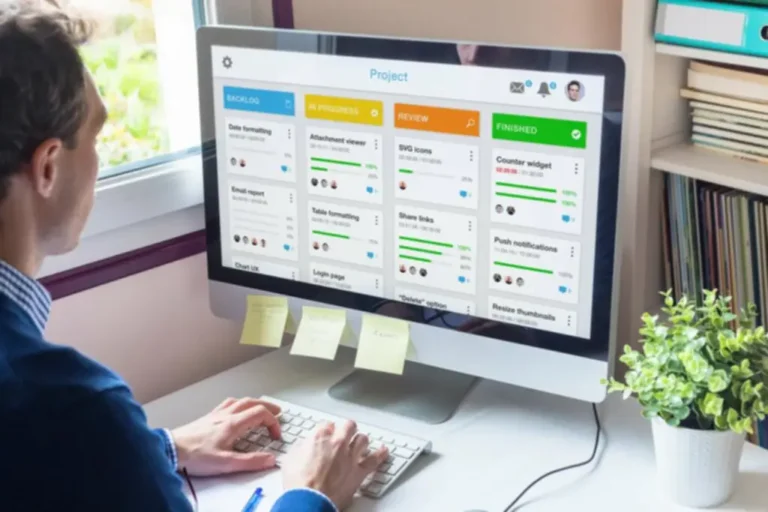

Frequently review and analyze these metrics to identify areas for additional improvement and ensure your Lean journey stays on track. Using playing cards or a Kanban board, you visualize your workflow, signaling when new work is needed and showing the status of work in progress. This “pull system” ensures duties are completed only when necessary, optimizing workflow and decreasing wasted time and effort. It’s like a traffic management system for your projects, stopping bottlenecks and preserving things flowing smoothly. Kanban helps you prioritize effectively and avoid overwhelming your staff, leading to improved efficiency and project supply. When you empower staff to identify areas for enchancment and give them possession over their work, you foster a way of objective and engagement.

Start with a small pilot project centered on a specific process with clear pain points. This lets you show the worth of lean shortly and build momentum for broader implementation. 5S is a good example of a lean tool that may ship quick, visible improvements in workplace organization and effectivity. That’s where the means ahead for lean will get really interesting, and the place expertise and long-term pondering come into play.

Prior to that, Jon held a selection of senior IT positions with hospital-giant HCA and its logistics subsidiary, HealthTrust Purchasing Group. He was amongst those responsible for launching HCA’s adoption of Lean-Agile methods. Lean methodology roots lie in streamlining production processes within the automobile trade, so it is smart that some practitioners should still are inclined to see it via the lens of cost-cutting and driving efficiencies. In the top, what matters most is discovering the proper tempo of change to ensure sustainability and momentum because shifting your operations towards a Digital Manufacturing System will take time. The winners within the subsequent decade might be those who recognize that digital transformation isn’t a one-time occasion.

The lean life cycle begins with project planning, followed by iteration planning. This precept urges teams to demonstrate responsible decision-making by keeping their choices open and continuously gathering data rather than making selections without required data. Lean software program growth is one of the groundbreaking methodologies to have revolutionized the whole value stream in IT. Lean thinking as a philosophy is made up of a set of common rules and values. These values can then be utilized utilizing tried-and-true tools and techniques depending on what a company (or individual manager) is making an attempt to realize.

This gives them the chance to delay making up their minds about what they actually require until they achieve better data. An agile software improvement approach can transfer the constructing of choices earlier for purchasers, thus delaying sure essential selections till prospects have realized their wants higher. This also allows later adaptation to modifications and the prevention of pricey earlier technology-bounded selections.

Too typically, organizations segregate the individuals growing new merchandise, processes, and providers innovation from the manufacturing and delivery https://communityfoodies.com/how-can-you-become-a-home-barista-on-a-budget/ parts of the enterprise, fragmenting the value chain. This approach causes delays, cost overruns, quality problems, and a bunch of other points. Worse, it can do large injury both to the tradition and general efficiency of the group. Lean Product and Course Of Improvement (LPPD) counters this tendency by bringing the whole organization together in the innovation course of.

This lets you goal your improvement efforts exactly the place they’re needed most. Waste isn’t just physical; it can be time wasted in unnecessary conferences or resources spent on tasks that don’t deliver worth. Lean management helps establish and remove these hidden drains on your budget. Businessmap highlights how this waste reduction immediately interprets to cost financial savings. By streamlining processes and utilizing assets more effectively, you may release finances for initiatives that actually drive development. Imagine redirecting these saved sources in course of innovation or customer acquisition—Lean helps make that attainable.

Assume of it like frequently updating software program to repair bugs and add new features—it’s an ongoing strategy of refinement. This commitment to continuous enchancment ensures your group remains adaptable and competitive. The Lean method offers the lean and agile principles have several benefits, together with improved productiveness, larger buyer satisfaction, lowered waste, and elevated adaptability. For instance, implementing Lean Development requires a cultural shift and could also be challenging for organizations accustomed to conventional development methodologies. Additionally, the emphasis on delivering fast could lead to rushed choices and quality points if not managed effectively.

It’s a framework many organizations use to streamline their processes and scale back waste, in the end offering more value to their clients. Lastly, and maybe most significantly, ClearPoint helps organizations connect their day-to-day efforts with their overarching strategic targets. By linking duties directly to strategic aims and performance measures, teams can ensure that every motion contributes to the larger image. This alignment is crucial for lean administration, because it maximizes effectivity and effectiveness, guaranteeing that everyone is rowing in the same direction. It’s like having a compass for your strategy, guiding each action in the course of true north.

The lean methodology is all about eliminating waste and improving effectivity to maximize and ship constant customer value. Underneath lean, if a process doesn’t convey value to the shopper, it’s thought of wasteful and is eliminated or lowered as a lot as attainable. It’s a growth method and guiding mindset that helps groups refine their processes within the name of effectivity, effectiveness, and continuous improvement. This process follows a structured strategy, emphasizing steady improvement, buyer worth, and the elimination of unnecessary duties.

The core ideas of Lean methodology have been developed with both of these elements. Like NASA mission management specialists, project managers should observe quite a few aspects to make sure their staff delivers tasks without incident. Lean organizations respect their staff by empowering them to be downside solvers and choice makers – giving them, in Dan Pink’s words, the autonomy, mastery, and objective to carry out at a excessive stage.

Lean Development discourages optimizing individual components at the expense of the overall system. As An Alternative, it encourages a holistic view of the event course of, aiming to optimize the whole value stream, from ideation incremental growth to delivery, to achieve most efficiency and buyer satisfaction. Lean Improvement emphasizes delivering worth to the shopper as rapidly as attainable. This lean development principle requires environment friendly https://www.wokitoki.org/racing-car-games-certainly-the-best-choice-for-car-drivers/ collaboration, constant feedback, and a give consideration to delivering the minimal viable product (MVP) to maximise buyer worth. By prioritizing the delivery to ensure quality of defect-free software, teams can cut back rework and improve buyer satisfaction. The lean methodology framework focuses on maximizing profits by reducing waste and understanding the utmost amount customers are willing to pay for a product.